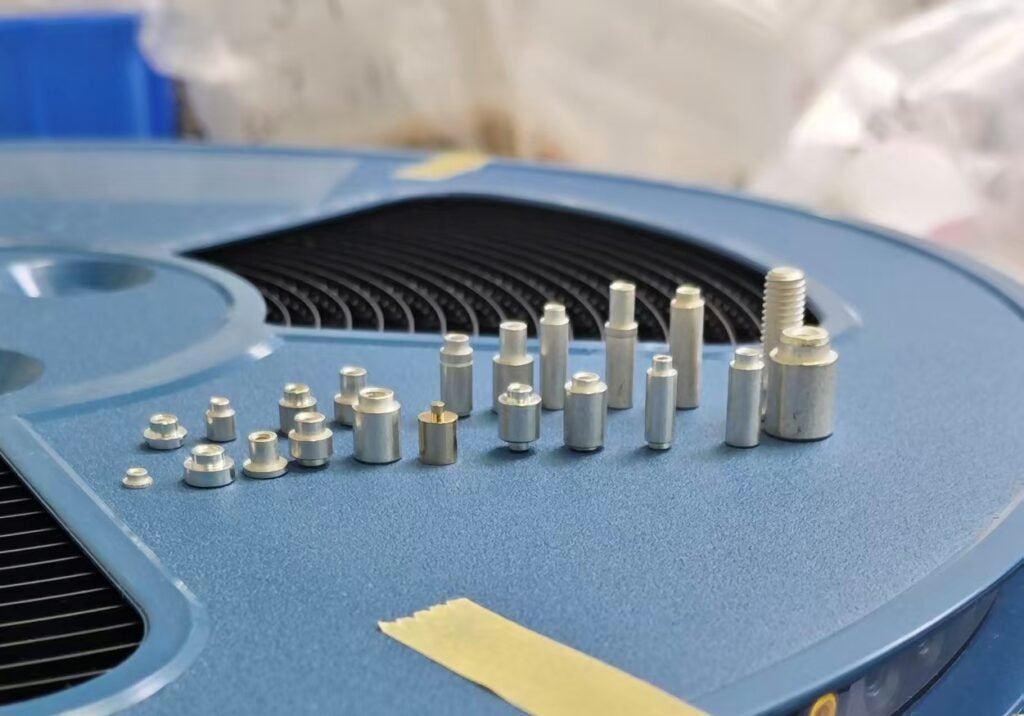

CNC / Machined Parts & Stamped Components

Traits: heavier metal parts, irregular shapes.

thicker embossed carrier tape

deep or special-shape cavities

high-strength materials (PS/PC)

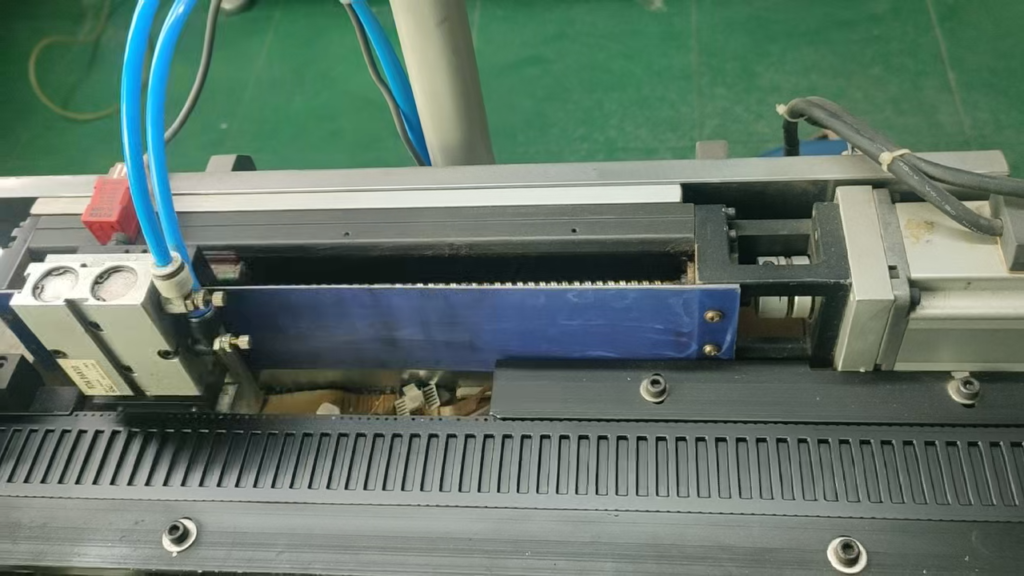

SMD Nuts / Spring Clips / Busbars

Traits: strong directionality, prone to flipping.

cavity limiters and orientation guides

anti-flip structures

optimized pick-up angle

Crystals / Connectors / Switches

Traits: more complex geometry, tight tolerance needs.

high-precision embossing

strict pitch/hole control

transparent or ESD material as required

Diodes / Transistors / ICs

Traits: very small parts, ESD-sensitive, high-density feeding.

anti-static carrier tape

fine-pitch cavities

controlled cover tape peel force

The 3 Core Rules

cavity must fit and stabilize the part

sprocket pitch must match feeders (EIA-481-C)

material & cover tape must seal correctly

Conclusion

Choosing the right carrier tape reduces line problems and saves cost. A professional source factory should help you match tape design to both component and equipment.

Hi, this is a comment.

To get started with moderating, editing, and deleting comments, please visit the Comments screen in the dashboard.

Commenter avatars come from Gravatar.