Overseas customers worry most about two things: late delivery and quality fluctuation. Since carrier tape is a high-consumption item once production starts, factory capacity directly impacts supply reliability.

Carrier Tape Is a Continuous-Use Product

Once your SMT line goes into mass production, carrier tape becomes a daily-use consumable. If supply breaks:

lines stop

you’re forced to switch suppliers

new validation costs time and money

What High-Capacity Factories Can Do Better

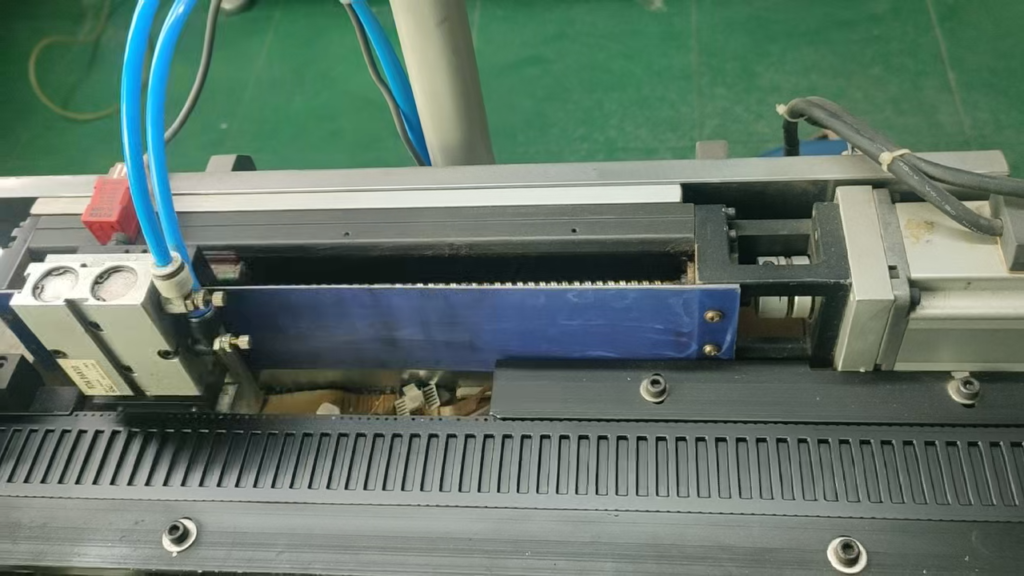

A manufacturer with multiple forming and reel packaging machines can:

run multiple specs in parallel

avoid long queues in peak seasons

respond fast to urgent orders

deliver large volume more consistently

Real Value of Daily Capacity

High capacity means risk control:

shorter lead time for big orders

no shortages during busy seasons

stable repeat supply for long-term programs

backup equipment and safety stock systems

Benefits for Global Buyers

predictable delivery schedules

better supply-chain control

easier to commit lead times to your own customers

ideal for long-term, multi-project sourcing

Summary

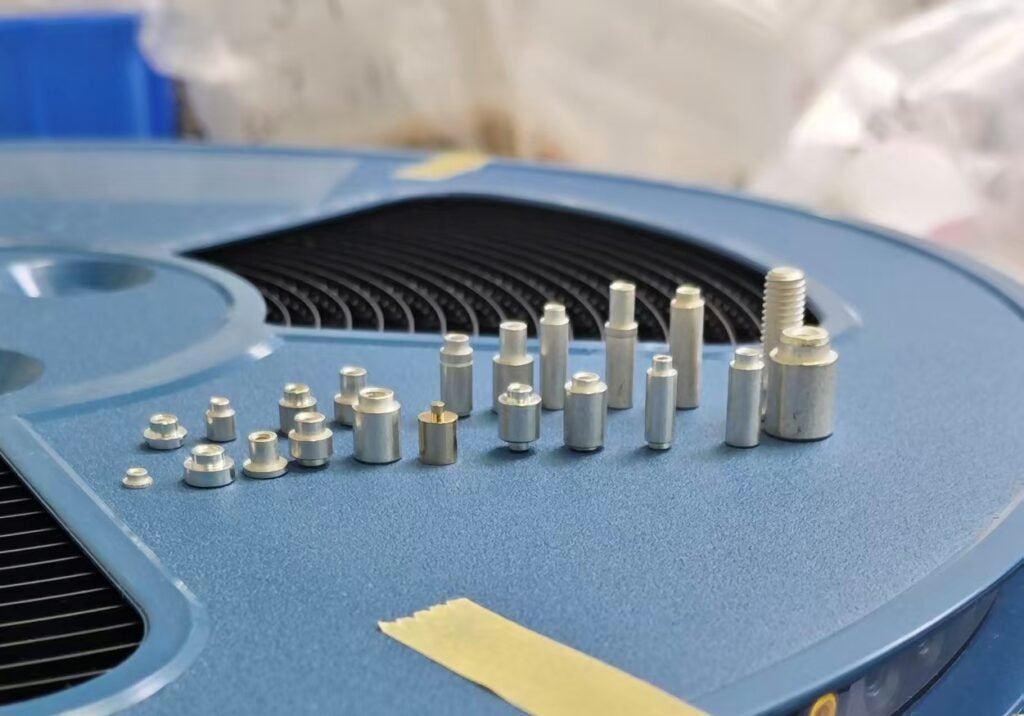

When choosing a carrier tape supplier, don’t just look at one shipment—look at whether they can supply you consistently for the long run. A high-capacity factory makes that possible.

Get a Free Carrier Tape Quote

Send us your component specs or samples. Our engineers will recommend the best carrier tape solution within 24 hours.